2022 has brought new life to our Kingsport Mill. In addition to 31,500 tons of material from the mill’s original structures being recycled to form the foundation for the mill’s future, employees who once made paper there are set to return to work as new buildings rise in the place where the others stood for more than a century.

Construction isn’t the only new life being breathed into the mill. The site is buzzing again as employees prepare to return to work and get accustomed to the mill’s new layout, containerboard product and processes.

With all the changes to the site, even long-time employees are having to relearn their way around.

“It’s really easy to get turned around,” says Nikki Armstrong, a paper machine operator who returned to work on Jan. 5.

Return to Work Brings New Opportunities

Armstrong, a seven-year mill employee, says coming back was like a family reunion. “I was super excited to get back and see my brothers and sisters.”

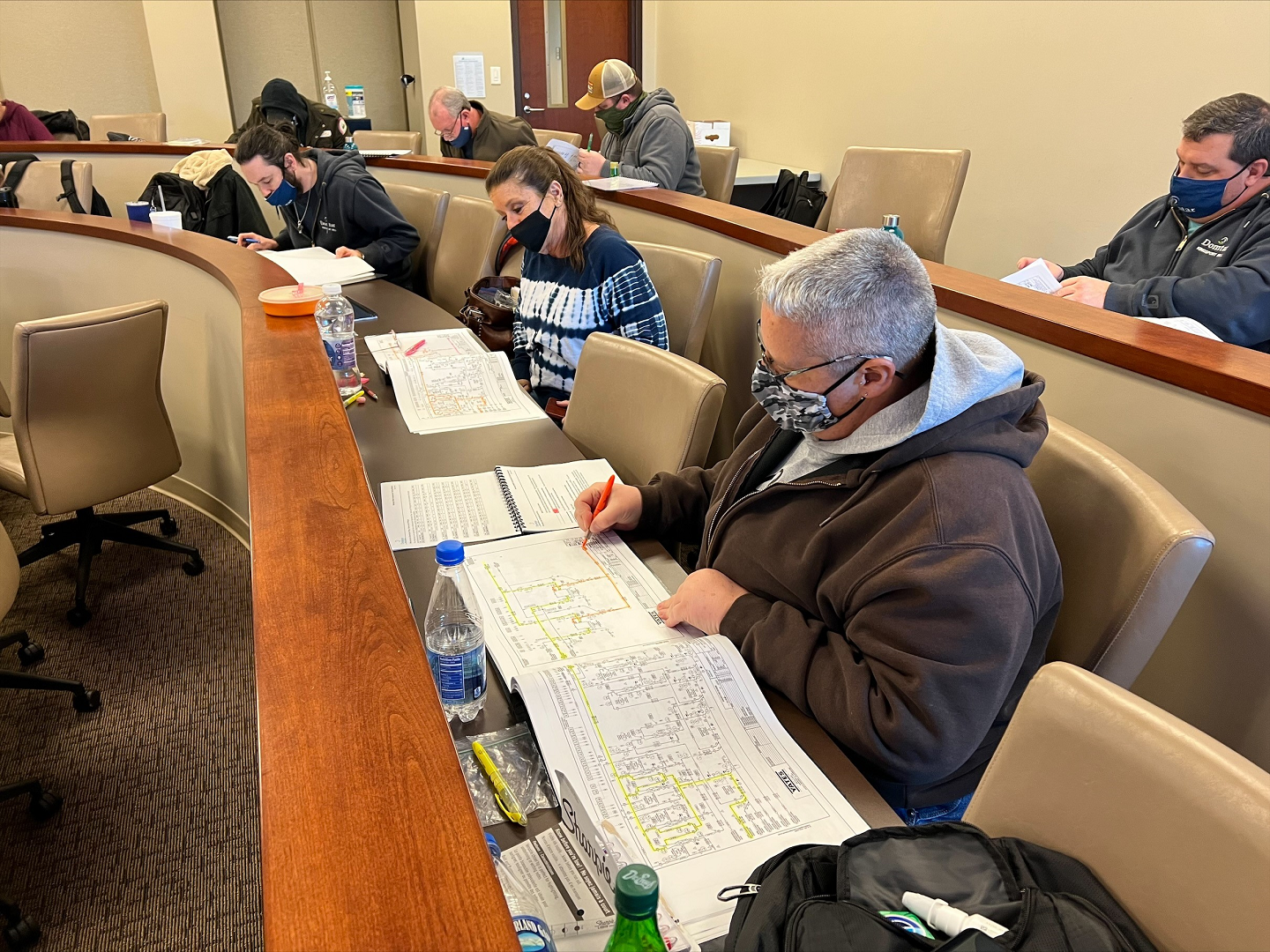

Since returning, Armstrong and her colleagues have been attending training courses that range from safety refreshers to specific learning for new production roles.

“The shutdown presented a unique opportunity to establish and implement a whole new work design,” says Mill Manager Troy Wilson. “We were able to reevaluate the workflow and design a schedule to meet our production needs while also providing a better quality of life for our employees.”

The new approach is a high-performance work system with a focus on flow to work and pay for skills. The new work design, coupled with a new work schedule, gives employees a better quality of life by allowing employees more time off.

“The 12-hour schedule is something we wanted before the mill shut down,” says Armstrong. “We’re excited to get the opportunity to spend more time with friends and family outside of work.”

“The leadership team reported back to the mill on October, followed by team leaders,” says Wilson. “Maintenance team and employees in the power area family were the first wave to come back on Nov. 29. The machine family reported on Jan. 5, and rest of the staff is due back by the beginning of February.”

After a great start to 2022, the mill’s future will only get better. Its transformation from paper to containerboard production was featured in the January edition of the Business Journal of the Tri-Cities Tennessee/Virginia. Construction is expected to be completed in the second quarter. The machine is expected to start in the fourth quarter of 2022, with full production expected by the end of the year.

Armstrong is optimistic about what the future holds.

“I’m excited to work in the machine family, and I plan to be here until I retire,” she says. “I think it was a very intelligent move for Domtar to get into containerboard.”

Read more about our Kingsport Mill conversion:

- Domtar to Enter Containerboard Market with Kingsport Mill Conversion

- Coming to Your Doorstep: Recycled Containerboard from Kingsport Mill

- Tennessee Senator Impressed by Kingsport Mill Conversion Progress